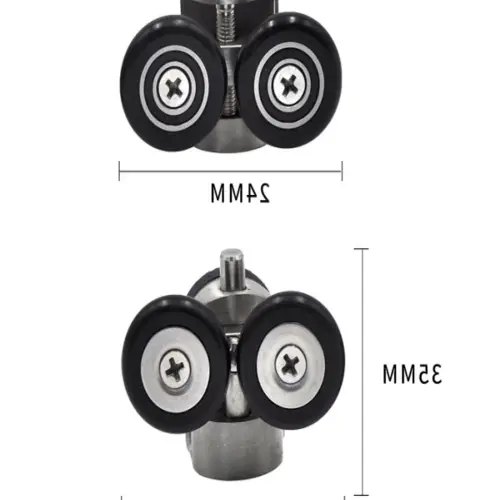

China Supplier Office Hanging Wheel Stainless Steel Glass Sliding Door Roller Track Pulley

Welcome to our website, where you can find the best quality office hanging wheel stainless steel glass sliding door roller track pulley. Our product, model DDGS157, is made of high-quality stainless steel and comes in various finishes including SSS, PSS, BP, GP, AB, AC, and MB. It is the perfect accessory for glass doors and shower doors. With its sturdy construction and smooth sliding mechanism, it ensures easy and reliable operation.

Product Description

| Product name | Office Hanging Wheel Stainless Steel Glass Sliding Door Roller Track Pulley |

| Product Model | DDGS157 |

| Material | Stainless steel |

| Finish | SSS, PSS, BP, GP, AB, AC,MB |

|

Accessories |

screws |

|

Suitable for |

glass door, shower door |

Packaging & Shipping

| MOQ | 200 pieces |

| Package | 1 pair per inner box, with export standard carton |

| Sample time | 5-7 working days |

| Production lead time | 30-35 days normally |

| Shipping Port | HangZhou, China / HangZhou, China |

| Payment | T/T, D/P, L/C, Western Union |

Testing

Our product has undergone rigorous testing to ensure its quality and performance. It meets international standards such as CE and UL, guaranteeing its reliability and safety.

Frequently Asked Questions

Q: What certificate do you have?

A: We have CE and UL certificates. Our product design follows international standards, such as EN/CE, UL, and ANSI.

Q: Do you accept OEM or ODM?

A: Yes, we are experienced in OEM and ODM. We have collaborated with famous brands for customized designs.

Q: Do you have a quality system?

A: Yes, we have implemented a comprehensive quality system to ensure the highest standards in our production process.

Q: What’s the guarantee of your products?

A: Our products come with a 5-year mechanical guarantee, providing you with peace of mind.

Q: What’s the stainless steel grade you are working with?

A: We primarily work with SUS304 and SUS316 stainless steel, although some items may also be made from SUS201.

Other Products

In addition to our office hanging wheel stainless steel glass sliding door roller track pulley, we offer a wide range of industrial products. Our product line includes agricultural gearboxes, power output shafts, sprockets, fluid couplings, worm gear reducers, gears and racks, roller chains, pulleys, planetary gearboxes, timing pulleys, bushings, and more. We take pride in providing high-quality products, competitive prices, and excellent customer service. We welcome custom drawings and samples to meet your specific requirements.

Disclaimer: The content of this page is sourced from the internet and is provided solely as a reference for product selection. Our products are replacement parts and not original spare parts. We are not the holder of the original trademarks mentioned in the content. Our replacement parts are designed to perfectly adapt to the original spare parts. If you require original spare parts, please contact the original factory or supplier for purchase.

Performance Characteristics of Stainless Pulley

Stainless pulleys possess several performance characteristics that make them highly efficient and reliable. Firstly, they exhibit exceptional corrosion resistance, ensuring longevity even in harsh environments. Secondly, the stainless steel material used in their construction provides high strength and durability, enabling them to withstand heavy loads. Additionally, stainless pulleys offer low friction, resulting in smoother and more efficient operation. Furthermore, they have excellent heat resistance, making them suitable for applications in high-temperature environments. Lastly, stainless pulleys are known for their low maintenance requirements, providing cost-effective solutions for various industries.

Types and Characteristics of Stainless Pulley

Stainless pulleys come in various types, each with its unique characteristics. One common type is the single groove pulley, which is widely used in industries requiring simple power transmission. Another type is the double groove pulley, which provides increased belt stability and improved power transmission efficiency. Additionally, there are also stainless pulleys with built-in bearings, offering smooth rotation and reduced friction. These pulleys are commonly used in conveyor systems and other applications that require precise movement. Furthermore, stainless pulleys can be found in different sizes and configurations, catering to the diverse needs of industries.

Advantages of Stainless Pulley Materials

Stainless pulleys can be manufactured using various materials, each with its advantages. Stainless steel pulleys, for instance, offer excellent resistance to corrosion and high temperatures, making them suitable for demanding environments. Nylon pulleys, on the other hand, provide superior shock absorption and noise reduction, making them ideal for applications where noise is a concern. Additionally, aluminum pulleys are lightweight and offer good electrical conductivity, making them suitable for certain industrial applications. By selecting the appropriate material for the stainless pulley, users can optimize their performance based on specific requirements.

Application of Stainless Pulley

The versatility of stainless pulleys is evident in their wide application across various industries. In the food processing industry, stainless pulleys are crucial in conveyor systems, ensuring efficient and hygienic transportation of goods. Medical equipment manufacturers rely on stainless pulleys to ensure smooth and precise movement in critical devices. Chemical industries utilize stainless pulleys for their corrosion resistance and reliability in aggressive chemical environments. Water treatment plants rely on stainless pulleys for their exceptional durability and resistance to corrosion from water and chemicals. In the automotive industry, stainless pulleys play a vital role in power transmission systems, contributing to vehicle performance and efficiency. These examples highlight the significance of stainless pulleys in different fields, showcasing their value and importance.

Future Development and Opportunities

The future of stainless pulley products holds promising opportunities for further advancements. As industries continue to demand higher efficiency and durability, stainless pulleys are poised to evolve in terms of material advancements and design innovations. The growing focus on sustainability and energy efficiency also presents opportunities for stainless pulley manufacturers to develop eco-friendly solutions. Additionally, the integration of smart technologies and automation in various industries opens up possibilities for enhanced monitoring and control of stainless pulley systems. By staying at the forefront of technological advancements, manufacturers can seize these opportunities and contribute to the continued development of stainless pulley products.

Choosing a Suitable Stainless Pulley

Selecting the right stainless pulley involves considering several key factors. Firstly, the load capacity requirement should be carefully evaluated to ensure that the chosen pulley can withstand the intended load. Secondly, the material of the pulley should align with the specific application requirements, taking into account factors such as corrosion resistance, strength, and temperature resistance. Additionally, the diameter and size of the pulley should be determined based on the desired belt size and system requirements. The type of pulley, whether single groove or double groove, should be chosen depending on the specific power transmission needs. Lastly, the bore size of the pulley should match the shaft size for proper installation and reliable operation.

In conclusion, stainless pulleys offer exceptional performance characteristics, various types, and advantages based on different materials. Their widespread applications across industries demonstrate their value and importance. The future presents opportunities for further development, with advancements in materials, design, and technology. When choosing a stainless pulley, careful consideration of load capacity, material, diameter and size, type, and bore size is necessary to ensure optimal performance. By selecting the right stainless pulley, industries can enhance their productivity and reliability, contributing to overall operational efficiency.

Author: Dream