Product Description

Stainless Steel SS304 Hardware Rigging wire rope rolling bearing block pulley

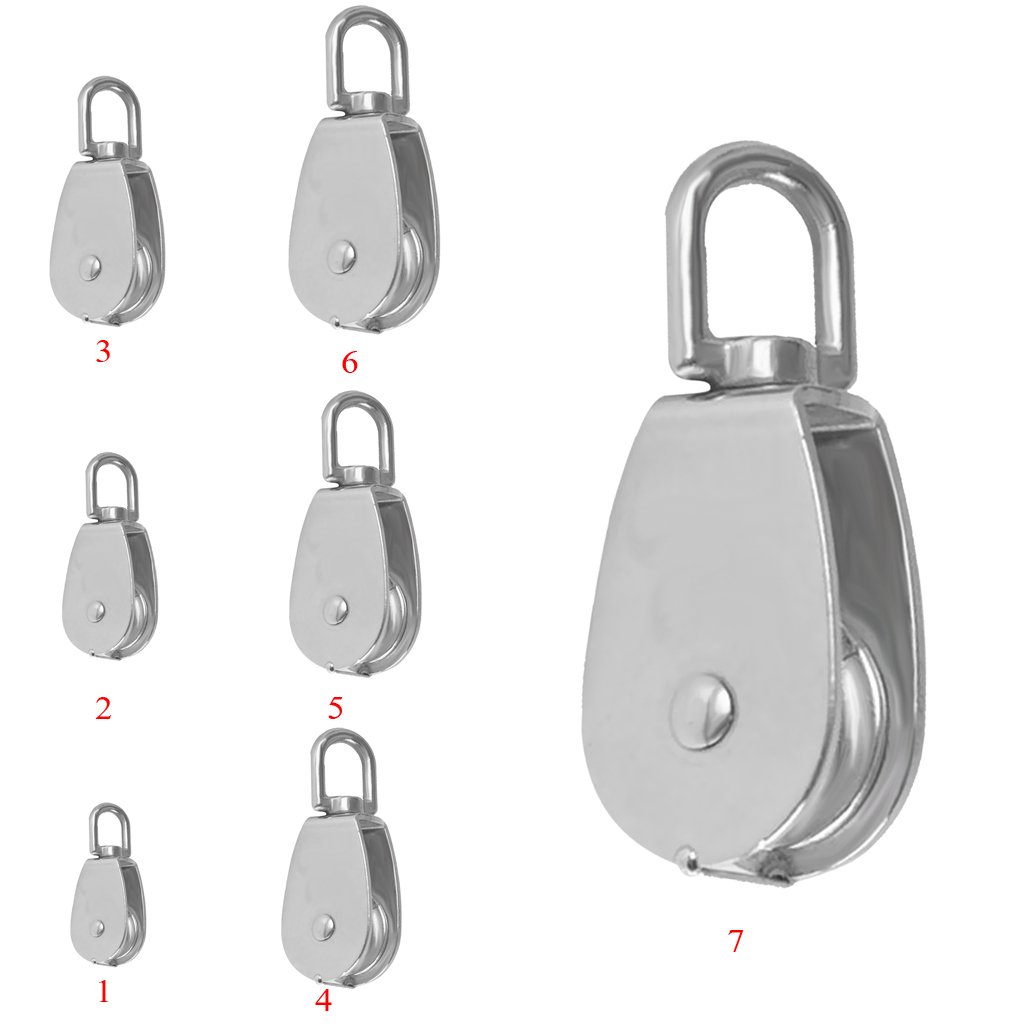

| Item | Wire Rope Pulley |

| Model | Single Pulley, Double Pulley |

| Size | M15-M100 |

| Material | Stainless Steel 304/316, Carbon Steel |

| Standard | DIN, ASME, BS, JIS, AS, EN, GB for option |

| Grade | A2-70, A4-80, 4.8/8.8 |

| Finish | Plain, Passivation, Polishing, Galvanized, Zinc Plated, Hot-dip Galvanized |

| Delivery Time | 3-15 days |

| OEM | Available |

Q: What’s your product range?

A: Our product cover Bolts, Screws, Nuts, Washers, Spring ,Rivet, Anchor, Pulley, Rigging and so on.

Q: How long is your delivery time?

A: 3 days for stock items,7-15 days for production.

Q: How do you control your quality.

A: QC on-line inspection and final inspection before delivery. 6S management. MTC and Quality Report can be provide.

Q: Could you provide free samples?

A: Yes, we could offer free samples for the items in stock, just need to pay shipping cost, it can be refunded to your orders.

Q: Do you accept small order?

A: Sure, we can accept small orders if we have stock of the specification which you need..

Q: What is your packing ?

A: 20-25kg for 1 carton,36 or 48 cartons for 1 pallet. One pallets is about 900-960kg. Customized carton and Customer’s logo is available.

Q: What is your payment term?

A: We can accept T/T, L/C for bulk order. Paypal and Western Union for small order or sample order.

Made-in-China Online payment is available.

Q: Do you accept customized order?

A: Yes, we can produce according to sample or drawing.

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Warranty: | 1 Year |

|---|---|

| Type: | Wire Rope Pulley |

| Material: | Stainless Steel/Carbon Steel |

| Number of sheaves: | Single Pulley, Double Pulley |

| Control: | Manual |

| Color: | Silver |

| Samples: |

US$ 0/Piece

1 Piece(Min.Order) | |

|---|

| Customization: |

Available

| Customized Request |

|---|

How do stainless pulleys contribute to the overall longevity and maintenance cost savings of equipment?

Stainless pulleys play a crucial role in enhancing the overall longevity of equipment and reducing maintenance costs. Here’s how they contribute:

- Corrosion Resistance: Stainless pulleys are made from stainless steel alloys that exhibit excellent corrosion resistance. This resistance allows the pulleys to withstand exposure to moisture, chemicals, and environmental factors without rusting or corroding. As a result, the pulleys maintain their structural integrity over time, extending the lifespan of the equipment.

- Durability: Stainless pulleys are highly durable and can withstand heavy loads, high pressures, and repetitive motion without deforming or failing. The inherent strength of stainless steel ensures that the pulleys can endure demanding operating conditions without compromising performance. This durability contributes to the longevity of the equipment.

- Reduced Wear and Tear: Stainless pulleys are designed to provide smooth and consistent operation. The precision-engineered grooves, diameter, and surface finish of the pulleys minimize friction and wear on belts or ropes. By reducing wear and tear, stainless pulleys help preserve the integrity of the entire system, including belts, ropes, and other components, thus extending their lifespan.

- Lower Maintenance Requirements: Stainless pulleys require minimal maintenance compared to pulleys made from other materials. Their corrosion resistance eliminates the need for frequent cleaning or protective coatings to prevent rust. Additionally, stainless steel’s resistance to wear and fatigue reduces the need for frequent pulley replacements. The lower maintenance requirements result in cost savings and reduce equipment downtime.

- Compatibility with Harsh Environments: Stainless pulleys are well-suited for use in harsh environments, such as those with high humidity, temperature variations, or exposure to chemicals. The corrosion resistance and durability of stainless steel enable the pulleys to maintain their performance even under challenging conditions. This compatibility with harsh environments enhances the overall longevity of the equipment.

- Resistance to Contamination: Stainless pulleys have a smooth surface finish that resists contamination and buildup of debris or particulates. This feature reduces the risk of contaminants entering the equipment and causing malfunctions or damage. By minimizing contamination, stainless pulleys contribute to the longevity and reliable operation of the equipment.

Overall, stainless pulleys contribute to the overall longevity and maintenance cost savings of equipment through their corrosion resistance, durability, reduced wear and tear, lower maintenance requirements, compatibility with harsh environments, and resistance to contamination. By investing in stainless pulleys, equipment owners can enjoy extended equipment lifespan, reduced maintenance expenses, and increased operational efficiency.

How are stainless pulleys customized for specific applications and load-bearing requirements?

Stainless pulleys can be customized to meet specific applications and load-bearing requirements. Here are some common methods and considerations for customizing stainless pulleys:

- Size and Dimensions: Stainless pulleys can be manufactured in various sizes and dimensions to accommodate different belt widths, rope diameters, or cable sizes. Customizing the size ensures proper fit and alignment with the rest of the system.

- Load Capacity: The load-bearing capacity of a pulley is a critical factor in its customization. Stainless pulleys can be designed to handle specific load requirements by adjusting the material thickness, reinforcing the structure, or using high-strength stainless steel alloys.

- Bearing Type: Pulleys can utilize different types of bearings depending on the application requirements. Customization involves selecting the appropriate bearing type, such as ball bearings or roller bearings, to ensure smooth rotation and efficient power transmission.

- Coatings and Finishes: Stainless pulleys can be customized with coatings or finishes to enhance their performance. For example, a non-stick coating can be applied to reduce friction and prevent material buildup. Corrosion-resistant coatings can be used for added protection in corrosive environments.

- Special Features: Depending on the application, stainless pulleys can be customized with special features. This may include flanges, grooves, or specific profiles to accommodate unique belt or rope configurations. Custom features can optimize the pulley’s interaction with the rest of the system.

- Environmental Considerations: Customization of stainless pulleys also takes into account the specific environmental conditions in which they will be used. Factors such as temperature extremes, exposure to chemicals or moisture, or compliance with industry regulations are considered to ensure the pulleys are suitable for the intended environment.

Customizing stainless pulleys for specific applications and load-bearing requirements requires collaboration between pulley manufacturers, engineers, and end-users. By considering factors such as size, load capacity, bearing type, coatings, special features, and environmental conditions, stainless pulleys can be tailored to provide optimal performance, reliability, and longevity in a wide range of industrial applications.

How does the use of stainless steel in pulleys impact their performance in challenging environments?

The use of stainless steel in pulleys has a significant impact on their performance in challenging environments. Here are the key ways in which stainless steel enhances pulley performance:

- Corrosion Resistance: Stainless steel exhibits excellent corrosion resistance, making it highly suitable for challenging environments where exposure to moisture, chemicals, or other corrosive substances is prevalent. The corrosion-resistant properties of stainless steel enable pulleys to maintain their structural integrity and functionality over extended periods, even in harsh and corrosive conditions.

- Durability: Stainless steel is known for its exceptional strength and durability. When used in pulleys, stainless steel enhances their ability to withstand heavy loads, high speeds, and repetitive use without deformation or failure. This durability ensures reliable performance and minimizes the risk of premature wear or damage, even in demanding and challenging environments.

- Temperature Resistance: Stainless steel pulleys can withstand a wide range of temperatures, making them suitable for challenging environments with extreme heat or cold. They retain their mechanical properties and dimensional stability, ensuring consistent performance and reliable operation in environments with temperature variations.

- Chemical Resistance: Certain industries or applications may involve exposure to chemicals or corrosive agents. Stainless steel pulleys, with their resistance to chemical reactions, are well-suited for such environments. They can withstand contact with various chemicals without undergoing degradation, ensuring long-term performance and operational reliability.

- Low Maintenance: Stainless steel pulleys require minimal maintenance due to their inherent properties. Their corrosion resistance reduces the need for frequent cleaning, inspection, or replacement, resulting in lower maintenance costs and increased operational efficiency in challenging environments.

- Hygienic Properties: In industries such as food processing or pharmaceutical manufacturing, maintaining cleanliness and hygiene is crucial. Stainless steel pulleys are hygienic and easy to clean, as they do not harbor bacteria or contaminants. This property ensures compliance with strict industry standards and facilitates safe and sanitary material handling in challenging environments.

In summary, the use of stainless steel in pulleys significantly enhances their performance in challenging environments. The corrosion resistance, durability, temperature resistance, chemical resistance, low maintenance requirements, and hygienic properties of stainless steel contribute to the reliability, longevity, and efficiency of pulleys in demanding industrial applications.

editor by CX

2024-05-17