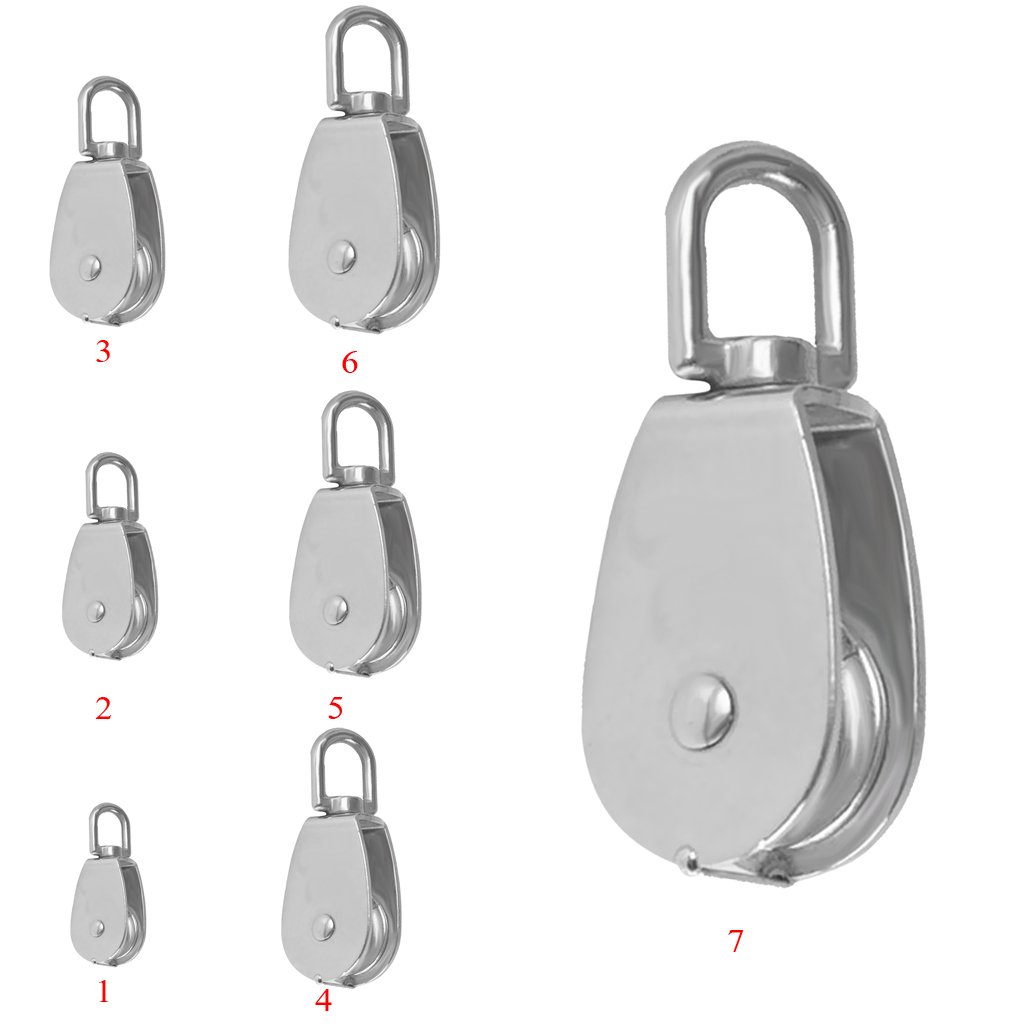

Product Description

| Product name | Manufacturer Stainless Steel U Groove Pulley Wheels For Window |

| Model number | Window Roller |

| Bore size | 5-10mm |

| Outside size | 5-5mm |

| Bearing material | Chrome steel, carbon steel, iron, high carbon steel |

| MOQ | 50000 PCS |

| Price terms | EXW, FOB, CIF |

| Payment terms | T/T, L/C, Paypal, Credit card |

| Production time | Depends on the quantity, normally 35-45 days. |

| Package | PE bag+white box+outer carton+pallet, or as customers’ requirement. |

| Application | Used in door, window, furniture and sports equipment. |

1. Pre-sale service: Our professional sales will reply your inquiry within 48 hours and introduce the structure and usage of the products.

2. On-purchase service: After customers placed the order, we will prepare the goods ASAP to make sure the delivery on time. Any delay will be notified in advance.

3. After-sale service: If there is any damage during delivery, the cost will be taken by our company and if there is problem during the warranty period, we will replace or refund it.

4. OEM service: We have advanced technology and experienced technicians to support the professional customized all kinds of bearing to meet different requirements.

Q: Are your company is a trading company or manufacturer?

A:We have our own factory as well we do the trade by our selves.

Q:How long is your delivery time?

A:Usually 5-10 days if we have the stock,if not,it will be 25-35 days. But it always depend on the quantity.

Q:Do you provide the free samples?

A:Yes,we’d like to.But you need to pay the freight fee,or we will return the cost when receiving your order.

Q:Can you do the OEM/ODM services?

A:Of course we can,We can be customized according to your requirements or drawings.

| Warranty: | 1 Year |

|---|---|

| Certification: | CE |

| Splittable: | Splittable |

| Surface Treatment: | Aluminium |

| Material: | Nylon |

| Groove Diameter: | Customized |

| Samples: |

US$ 0.25/Piece

1 Piece(Min.Order) | |

|---|

| Customization: |

Available

| Customized Request |

|---|

Can stainless pulleys be retrofitted into existing systems for performance enhancements?

Yes, stainless pulleys can be retrofitted into existing systems to achieve performance enhancements. Here’s how:

- Compatibility Assessment: Evaluate the compatibility of stainless pulleys with the existing system. Consider factors such as pulley size, shaft diameter, groove dimensions, and belt or rope type. Ensure that the stainless pulleys can be seamlessly integrated into the system without compromising its overall functionality.

- Performance Analysis: Identify the performance goals or areas of improvement in the existing system. This could include increasing power transmission efficiency, reducing friction or wear, enhancing corrosion resistance, or meeting specific industry requirements. Determine how stainless pulleys can address these performance objectives.

- Proper Sizing and Design: Select the appropriate stainless pulleys based on the system’s requirements and performance goals. Consider factors such as pulley size, groove shape, and materials. Ensure that the new pulleys are properly sized and designed to optimize the system’s performance.

- Installation and Alignment: Follow proper installation procedures when retrofitting stainless pulleys. Ensure that the pulleys are aligned correctly with other system components such as belts, ropes, or shafts. Proper alignment minimizes misalignment-related issues, reduces wear, and maximizes power transmission efficiency.

- Maintenance Considerations: Evaluate any changes in maintenance requirements after retrofitting stainless pulleys. Stainless pulleys may have different maintenance needs compared to the previous pulleys. Ensure that maintenance schedules and procedures are adjusted accordingly to maximize the benefits of the new pulleys.

- System Testing and Validation: After retrofitting the stainless pulleys, conduct thorough testing and validation to ensure that the performance enhancements are achieved. Monitor factors such as power transmission efficiency, system vibration, noise levels, and overall system functionality. Make any necessary adjustments or fine-tuning to optimize the system’s performance.

- Expert Consultation: If needed, consult with pulley manufacturers, engineers, or industry experts during the retrofitting process. They can provide valuable guidance and expertise in selecting the right stainless pulleys, ensuring compatibility, and optimizing the system’s performance.

By carefully assessing compatibility, identifying performance goals, selecting the appropriate stainless pulleys, ensuring proper installation and alignment, considering maintenance adjustments, conducting thorough testing, and seeking expert advice when necessary, existing systems can be retrofitted with stainless pulleys to achieve performance enhancements.

What role do stainless pulleys play in ensuring clean and hygienic operations in certain industries?

Stainless pulleys play a crucial role in ensuring clean and hygienic operations in certain industries. Here’s how they contribute to maintaining cleanliness and hygiene:

- Material Composition: Stainless pulleys are typically made from stainless steel, a material known for its hygienic properties. Stainless steel is non-porous, resistant to bacteria, and easy to clean, making it suitable for industries where cleanliness is paramount.

- Smooth and Seamless Surfaces: Stainless pulleys are designed with smooth and seamless surfaces, reducing the potential for dirt, debris, or contaminants to accumulate. The absence of crevices or rough surfaces makes it easier to clean the pulleys thoroughly, ensuring that no bacteria or other contaminants are left behind.

- Resistance to Corrosion: Stainless steel is highly resistant to corrosion, which is essential for industries that require frequent cleaning or exposure to cleaning agents and disinfectants. The corrosion-resistant nature of stainless pulleys ensures that they can withstand regular cleaning processes without degradation or compromising their hygienic properties.

- No Risk of Contamination: Stainless pulleys do not shed particles, rust, or corrode, ensuring that they do not contaminate the surrounding environment or the products being handled. This is particularly important in industries such as food processing, pharmaceuticals, or cleanrooms, where even the slightest contamination can have serious consequences.

- Compliance with Regulations: Industries such as food and beverage, pharmaceuticals, and healthcare are subject to stringent regulations and standards regarding cleanliness and hygiene. Stainless pulleys help these industries meet regulatory requirements by providing a hygienic material choice that can be easily cleaned, sanitized, and maintained.

- Longevity and Reliability: Stainless pulleys offer excellent durability and longevity, reducing the need for frequent replacements. This ensures that the pulleys can maintain their hygienic properties over an extended period, contributing to the overall cleanliness and hygiene of the operations.

In summary, stainless pulleys play a vital role in ensuring clean and hygienic operations in industries that require strict cleanliness standards. Their material composition, smooth surfaces, resistance to corrosion, non-contaminating nature, compliance with regulations, and longevity contribute to maintaining a hygienic environment and preventing contamination in industries such as food processing, pharmaceuticals, healthcare, and others.

How does stainless steel enhance the durability and corrosion resistance of pulleys?

Stainless steel enhances the durability and corrosion resistance of pulleys through its unique properties. Here’s how stainless steel achieves these advantages:

- Corrosion Resistance: Stainless steel contains chromium, which forms a thin and invisible oxide layer on the surface of the pulleys. This oxide layer acts as a protective barrier, preventing the underlying steel from coming into direct contact with corrosive agents such as moisture, chemicals, or contaminants. The oxide layer effectively resists rusting and corrosion, ensuring the longevity and performance of the pulleys even in corrosive environments.

- Durability: Stainless steel is known for its excellent strength and durability. It has high tensile strength, allowing the pulleys to withstand heavy loads, high speeds, and repetitive use without deformation or failure. The inherent strength of stainless steel ensures that the pulleys can maintain their structural integrity and performance over extended periods, making them highly durable.

- Resistance to Wear and Abrasion: Stainless steel pulleys exhibit resistance to wear and abrasion, thanks to their hardness and surface properties. The stainless steel material has a high hardness level, making it less susceptible to surface damage caused by friction or contact with abrasive materials. This wear resistance ensures that the pulleys can withstand the demands of continuous use and maintain their functional and operational integrity for a longer time.

- High Strength-to-Weight Ratio: Stainless steel possesses a high strength-to-weight ratio, meaning it provides exceptional strength while being relatively lightweight. This characteristic is advantageous for pulleys as it allows for the design of lighter and more compact pulley systems without compromising strength and load-bearing capacity. The reduced weight of stainless steel pulleys can contribute to overall system efficiency and ease of installation.

- Tolerance to Extreme Temperatures: Stainless steel pulleys can withstand a wide range of temperatures, from very high to very low. They retain their mechanical properties and dimensional stability even when exposed to extreme temperature variations. This temperature resistance makes stainless steel pulleys suitable for applications that involve heat, cold, or thermal cycling, ensuring consistent and reliable performance in diverse environments.

In summary, stainless steel enhances the durability of pulleys by providing corrosion resistance, wear resistance, high strength-to-weight ratio, and tolerance to extreme temperatures. These properties make stainless steel pulleys highly reliable and long-lasting, even in demanding industrial applications.

editor by CX

2023-10-11