Product Description

Product Description

A timing pulley is a wheel component used for transmission, which is often used in combination with a timing belt or a synchronous chain to achieve precision synchronous transmission. The timing pulley usually consists of 2 parts: the wheel flange and the hub. The wheel flange usually has a toothed structure that can be combined with a timing belt or chain to achieve a precise synchronous transmission effect. Synchronous wheels can be divided into 2 categories: grinding gear synchronous wheels and forged tooth synchronous wheels.

Product Parameters

| product | high precision and high quality Cone sleeve timing pulley |

| material | stainless steel , iron , aluminum ,bronze ,carbon steel ,brass etc . |

| size | ISO standard ,customer requirements |

| BORE | Finished bore, Pilot Bore, Special request |

| surface treatment | Carburizing and Quenching,Tempering ,Tooth suface high quenching Hardening,Tempering |

| Processing Method | Molding, Shaving, Hobbing, Drilling, Tapping, Reaming, Manual Chamfering, Grinding etc |

| Heat Treatment | Quenching & Tempering, Carburizing & Quenching, High-frequency Hardening, Carbonitriding…… |

| Package | Wooden Case/Container and pallet, or made-to-order |

| Certificate | ISO9001 ,SGS |

| Machining Process | Gear Hobbing, Gear Milling, Gear Shaping, Gear Broaching, Gear Shaving, Gear Grinding and Gear Lapping |

| Applications | Toy, Automotive, instrument, electrical equipment, household appliances, furniture, mechanical equipment,daily living equipment, electronic sports equipment, , sanitation machinery, market/ hotel equipment supplies, etc. |

| Testing Equipment | Rockwell hardness tester 500RA, Double mesh instrument HD-200B & 3102,Gear measurement center instrument CNC3906T and other High precision detection equipments |

workshop & equipment

Production process

Certifications

Our Advantages

1 . Prioritized Quality

2 .Integrity-based Management

3 .Service Orientation

4 .150+ advanced equipment

5 .10000+ square meter factory area

6 .200+ outstanding employees

7 .90% employees have more than 10 year- working experience in our factory

8 .36 technical staff

9 .certificate ISO 9001 , SGS

10 . Customization support

11 .Excellent after-sales service

shipping

sample orders delivery time:

10-15 working days as usual

15-20 working days in busy season

large order leading time :

20-30 working days as usual

30-40 working days in busy season

FAQ

1. why should you buy products from us not from other suppliers?

We are a 32 year-experience manufacturer on making the gear, specializing in manufacturing varieties of gears, such as helical gear ,bevel gear ,spur gear and grinding gear, gear shaft, timing pulley, rack, , timing pulley and other transmission parts . There are 150+ advanced equipment ,200+ excellent employees ,and 36 technical staff . what’s more ,we have got ISO9001 and SGS certificate .

2: What are the common types of tooth profiles for synchronous belt pulleys?

A: The most common tooth profiles for synchronous belt pulleys are the trapezoidal (or T-type) and curvilinear (or HTD-type) profiles. The tooth profile determines the pitch diameter, which affects the overall ratio of the gear drive.

3 .How long is the delivery?

A: Small orders usually takes 10-15 working days,big order usually 20-35 days, depending on orders quantity and whether are standard size.

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Certification: | ISO |

|---|---|

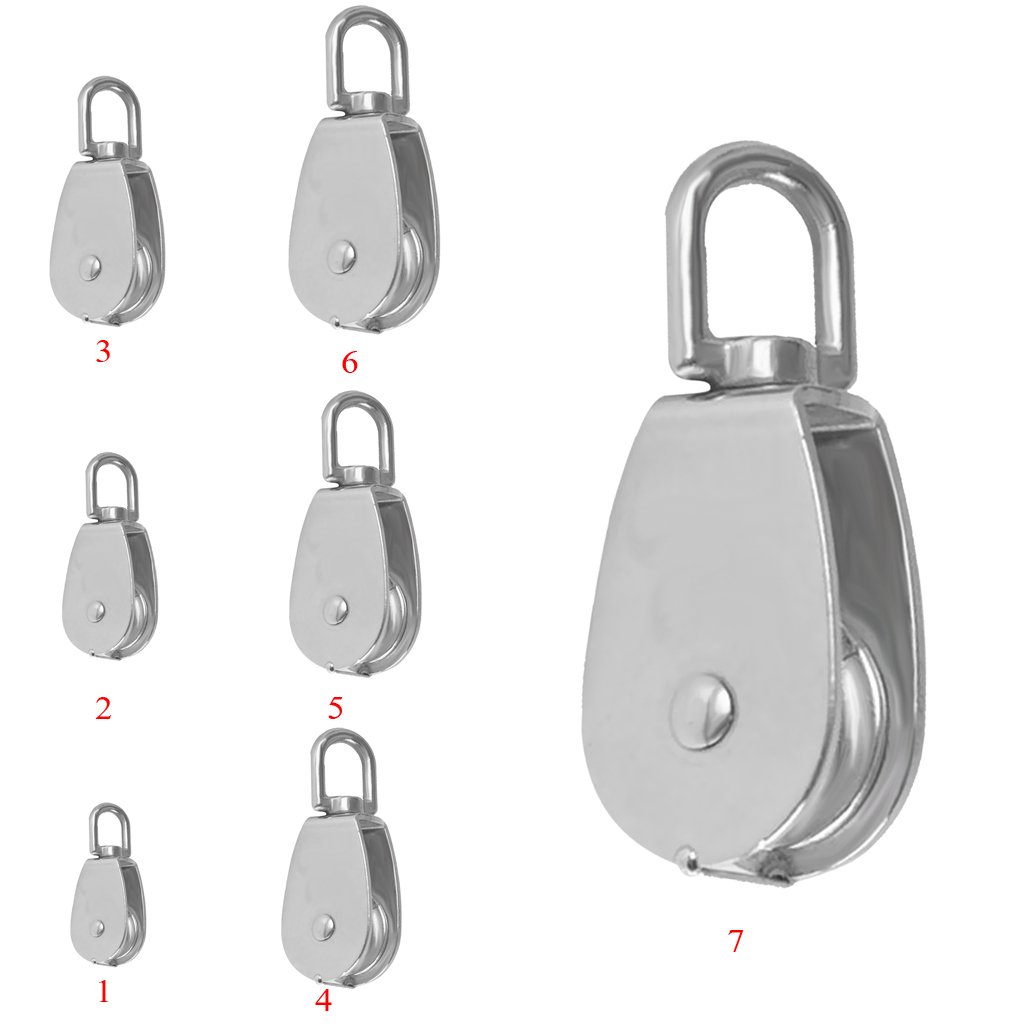

| Pulley Sizes: | Type F |

| Manufacturing Process: | Forging |

| Material: | Stainless Steel |

| Surface Treatment: | Electroplating |

| Application: | Chemical Industry, Grain Transport, Mining Transport, Power Plant |

| Samples: |

US$ 5/Piece

1 Piece(Min.Order) | |

|---|

| Customization: |

Available

| Customized Request |

|---|

Can stainless pulleys be retrofitted into existing systems for performance enhancements?

Yes, stainless pulleys can be retrofitted into existing systems to achieve performance enhancements. Here’s how:

- Compatibility Assessment: Evaluate the compatibility of stainless pulleys with the existing system. Consider factors such as pulley size, shaft diameter, groove dimensions, and belt or rope type. Ensure that the stainless pulleys can be seamlessly integrated into the system without compromising its overall functionality.

- Performance Analysis: Identify the performance goals or areas of improvement in the existing system. This could include increasing power transmission efficiency, reducing friction or wear, enhancing corrosion resistance, or meeting specific industry requirements. Determine how stainless pulleys can address these performance objectives.

- Proper Sizing and Design: Select the appropriate stainless pulleys based on the system’s requirements and performance goals. Consider factors such as pulley size, groove shape, and materials. Ensure that the new pulleys are properly sized and designed to optimize the system’s performance.

- Installation and Alignment: Follow proper installation procedures when retrofitting stainless pulleys. Ensure that the pulleys are aligned correctly with other system components such as belts, ropes, or shafts. Proper alignment minimizes misalignment-related issues, reduces wear, and maximizes power transmission efficiency.

- Maintenance Considerations: Evaluate any changes in maintenance requirements after retrofitting stainless pulleys. Stainless pulleys may have different maintenance needs compared to the previous pulleys. Ensure that maintenance schedules and procedures are adjusted accordingly to maximize the benefits of the new pulleys.

- System Testing and Validation: After retrofitting the stainless pulleys, conduct thorough testing and validation to ensure that the performance enhancements are achieved. Monitor factors such as power transmission efficiency, system vibration, noise levels, and overall system functionality. Make any necessary adjustments or fine-tuning to optimize the system’s performance.

- Expert Consultation: If needed, consult with pulley manufacturers, engineers, or industry experts during the retrofitting process. They can provide valuable guidance and expertise in selecting the right stainless pulleys, ensuring compatibility, and optimizing the system’s performance.

By carefully assessing compatibility, identifying performance goals, selecting the appropriate stainless pulleys, ensuring proper installation and alignment, considering maintenance adjustments, conducting thorough testing, and seeking expert advice when necessary, existing systems can be retrofitted with stainless pulleys to achieve performance enhancements.

Can stainless pulleys be used in outdoor applications subject to weather and moisture?

Yes, stainless pulleys are well-suited for outdoor applications subject to weather and moisture. Here’s why:

- Corrosion Resistance: Stainless steel is highly resistant to corrosion, including rust, making it an ideal choice for outdoor environments. It can withstand exposure to moisture, rain, humidity, and temperature fluctuations without degrading or rusting.

- Non-Reactive Properties: Stainless steel is non-reactive, meaning it does not easily interact with other substances. This property allows stainless pulleys to resist chemical reactions with environmental elements, pollutants, or contaminants that may be present in outdoor settings.

- Durability: Stainless steel is a durable material that can withstand harsh outdoor conditions. It is resistant to impact, UV radiation, and abrasion, ensuring that stainless pulleys can maintain their structural integrity and performance over time.

- Sealed Bearings: Many stainless pulleys are equipped with sealed bearings, which provide an additional layer of protection against moisture and contaminants. Sealed bearings help prevent water, dust, or debris from entering the bearing housing, ensuring smooth operation and extending the pulley’s lifespan.

- Proper Maintenance: Regular maintenance practices, such as cleaning, lubrication, and inspection, can further enhance the longevity of stainless pulleys in outdoor applications. By following recommended maintenance procedures, the pulleys can remain in optimal condition and continue to perform reliably.

It is important to note that while stainless pulleys are well-suited for outdoor environments, the specific grade and finish of stainless steel used can affect their performance. In highly corrosive or marine environments, it is advisable to use marine-grade stainless steel or additional protective coatings to provide extra resistance against saltwater and other corrosive agents.

Overall, stainless pulleys offer excellent durability, corrosion resistance, and reliability, making them a suitable choice for outdoor applications subject to weather and moisture.

In which industries and applications are stainless pulleys commonly used?

Stainless pulleys find extensive use in various industries and applications where their unique properties are highly advantageous. Here are some common industries and applications where stainless pulleys are commonly used:

- Food Processing: Stainless pulleys are widely utilized in the food processing industry due to their hygienic properties and corrosion resistance. They are used in conveyor systems for the handling and transportation of food products, ensuring clean and safe material flow.

- Pharmaceutical Manufacturing: The pharmaceutical industry requires strict adherence to cleanliness and hygiene standards. Stainless pulleys are used in pharmaceutical manufacturing processes where clean and sterile conditions are essential, such as in tablet counting machines or packaging lines.

- Chemical Processing: Stainless pulleys are suitable for industries involved in chemical processing, including chemical manufacturing plants and refineries. They can withstand exposure to corrosive chemicals and provide reliable performance in applications such as mixing, pumping, or conveying corrosive substances.

- Mining and Quarrying: In the mining and quarrying industry, stainless pulleys are used in conveyor systems to facilitate the transportation of mined materials. The durability and strength of stainless steel make it well-suited for handling heavy loads and abrasive materials.

- Wastewater Treatment: Stainless pulleys are employed in wastewater treatment plants where resistance to chemicals and corrosion is crucial. They are used in various equipment, such as belt filter presses or dewatering systems, to efficiently handle and process wastewater and sludge.

- Agriculture: Stainless pulleys are utilized in agricultural applications, including grain handling, seed processing, or livestock feed production. They provide reliable and efficient material handling solutions, ensuring smooth operations in agricultural facilities.

- Automotive and Manufacturing: Stainless pulleys find applications in the automotive and manufacturing industries, where they are used in assembly lines, robotic systems, or material handling equipment. Their durability and resistance to wear make them suitable for high-speed and repetitive operations.

- Packaging and Logistics: Stainless pulleys are employed in packaging and logistics industries to facilitate the movement of goods along conveyor systems. They ensure smooth and efficient transportation of packaged products, optimizing productivity and throughput.

- Architectural and Design: Stainless pulleys are also used in architectural and design applications for their aesthetic appeal. They can be incorporated into building facades, interior design elements, or decorative installations to provide both functionality and visual attractiveness.

These are just a few examples of the industries and applications where stainless pulleys are commonly used. The versatility, durability, and corrosion resistance of stainless steel make it a preferred choice in various sectors that require reliable and efficient material handling solutions.

editor by CX

2024-05-08