Product Description

Basic Info.

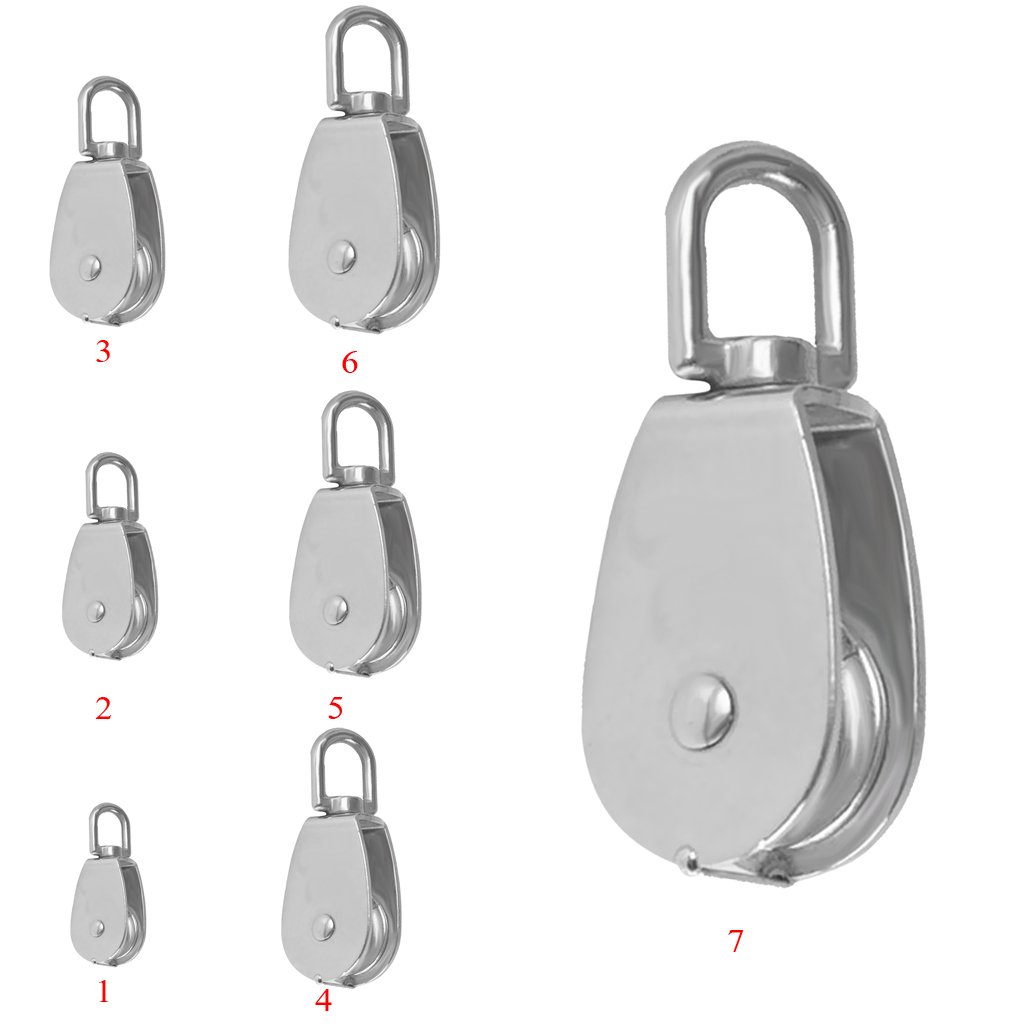

Material :AISI 304 AND AISI 316

| Model No. |

Stainless steel Pulley |

| Brand |

HUARUI |

| Design |

Casting |

| Function |

Assemble with Wire rope or Rigging |

| Certification |

SGS |

| For wire rope | fro 3mm to 20mm |

| Manufacture |

Casting |

| Color | Silver Color(with polished) |

| Transport Package |

Clean Poly Bags Plus Cartons Plus Pallets |

| Trademark |

HUARUI |

| Production Capacity |

100,000 pcs/Month |

Q: What is material you can supply?

A: Stainless steel 316 or stainless steel 304

Q: How long is your delivery time?

A: Generally it is 5-10 days if the goods are in stock. or it is 30-35 days if the goods are not in stock, it is according to quantity.

Q: Do you provide samples ? is it free or extra ?

A: Yes, we could offer the sample for free charge but do not pay the cost of freight.

Q: What is your terms of payment ?

A: Payment=1000USD, 30% T/T in advance ,balance CHINAMFG copy of B/L.

If you have another question, pls feel free to contact us at

Contact :Ms. Rita Sun

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Material: | AISI 304, AISI 316 |

|---|---|

| MOQ: | 100 |

| Useful: | Rigging |

| for Wire Rope: | 1/8" |

| Transport Package: | Clean Polybags and Cartons and Pallet |

| Specification: | customized |

| Samples: |

US$ 0.5/Piece

1 Piece(Min.Order) | |

|---|

| Customization: |

Available

| Customized Request |

|---|

What are some real-world examples of stainless pulley applications in food processing and pharmaceutical industries?

Stainless pulleys find various applications in the food processing and pharmaceutical industries, where strict hygiene standards and corrosion resistance are essential. Here are some real-world examples:

- Conveyor Systems: Stainless pulleys are commonly used in conveyor systems for transporting food products or pharmaceutical materials. They facilitate the movement of belts or chains, ensuring smooth and efficient material handling. Stainless pulleys in conveyor systems help maintain hygiene by being resistant to corrosion and easy to clean.

- Bottle Filling and Capping Machines: In the beverage and pharmaceutical industries, stainless pulleys are utilized in bottle filling and capping machines. These pulleys enable the precise movement and positioning of bottles during the filling and capping process. They contribute to accurate production rates and help ensure proper sealing and quality control.

- Mixing and Blending Equipment: Stainless pulleys are essential components in mixing and blending equipment used in food processing and pharmaceutical manufacturing. They assist in rotating the mixing blades or agitators, ensuring thorough blending of ingredients or substances. Stainless pulleys in these applications provide durability, corrosion resistance, and reliable performance.

- Vacuum Packaging Systems: Stainless pulleys are employed in vacuum packaging systems to facilitate the movement of packaging films or bags. These pulleys ensure proper tension and alignment of the packaging material during the sealing process. Stainless pulleys in vacuum packaging systems withstand the moisture, heat, and cleaning agents typically encountered in food and pharmaceutical production environments.

- Tablet Press Machines: In the pharmaceutical industry, stainless pulleys are utilized in tablet press machines. These pulleys assist in the precise movement and synchronization of punches and dies during the tablet compression process. Stainless pulleys in tablet press machines provide smooth operation, corrosion resistance, and adherence to strict hygiene standards.

- Confectionery Production Equipment: Stainless pulleys are used in various confectionery production equipment, such as chocolate tempering machines, enrobing machines, and candy coating drums. These pulleys contribute to the movement and precise alignment of conveyors, belts, or drums, ensuring consistent production quality and hygiene compliance.

- Pharmaceutical Packaging Machinery: Stainless pulleys are integral components in pharmaceutical packaging machinery, including blister packaging machines, cartoning machines, and labeling machines. They assist in the precise movement and handling of packaging materials, ensuring accurate packaging, labeling, and serialization.

These examples illustrate the wide range of applications where stainless pulleys are utilized in the food processing and pharmaceutical industries. By providing corrosion resistance, hygiene compliance, and reliable operation, stainless pulleys contribute to the efficiency, productivity, and quality assurance of these critical sectors.

How are stainless pulleys customized for specific applications and load-bearing requirements?

Stainless pulleys can be customized to meet specific applications and load-bearing requirements. Here are some common methods and considerations for customizing stainless pulleys:

- Size and Dimensions: Stainless pulleys can be manufactured in various sizes and dimensions to accommodate different belt widths, rope diameters, or cable sizes. Customizing the size ensures proper fit and alignment with the rest of the system.

- Load Capacity: The load-bearing capacity of a pulley is a critical factor in its customization. Stainless pulleys can be designed to handle specific load requirements by adjusting the material thickness, reinforcing the structure, or using high-strength stainless steel alloys.

- Bearing Type: Pulleys can utilize different types of bearings depending on the application requirements. Customization involves selecting the appropriate bearing type, such as ball bearings or roller bearings, to ensure smooth rotation and efficient power transmission.

- Coatings and Finishes: Stainless pulleys can be customized with coatings or finishes to enhance their performance. For example, a non-stick coating can be applied to reduce friction and prevent material buildup. Corrosion-resistant coatings can be used for added protection in corrosive environments.

- Special Features: Depending on the application, stainless pulleys can be customized with special features. This may include flanges, grooves, or specific profiles to accommodate unique belt or rope configurations. Custom features can optimize the pulley’s interaction with the rest of the system.

- Environmental Considerations: Customization of stainless pulleys also takes into account the specific environmental conditions in which they will be used. Factors such as temperature extremes, exposure to chemicals or moisture, or compliance with industry regulations are considered to ensure the pulleys are suitable for the intended environment.

Customizing stainless pulleys for specific applications and load-bearing requirements requires collaboration between pulley manufacturers, engineers, and end-users. By considering factors such as size, load capacity, bearing type, coatings, special features, and environmental conditions, stainless pulleys can be tailored to provide optimal performance, reliability, and longevity in a wide range of industrial applications.

In which industries and applications are stainless pulleys commonly used?

Stainless pulleys find extensive use in various industries and applications where their unique properties are highly advantageous. Here are some common industries and applications where stainless pulleys are commonly used:

- Food Processing: Stainless pulleys are widely utilized in the food processing industry due to their hygienic properties and corrosion resistance. They are used in conveyor systems for the handling and transportation of food products, ensuring clean and safe material flow.

- Pharmaceutical Manufacturing: The pharmaceutical industry requires strict adherence to cleanliness and hygiene standards. Stainless pulleys are used in pharmaceutical manufacturing processes where clean and sterile conditions are essential, such as in tablet counting machines or packaging lines.

- Chemical Processing: Stainless pulleys are suitable for industries involved in chemical processing, including chemical manufacturing plants and refineries. They can withstand exposure to corrosive chemicals and provide reliable performance in applications such as mixing, pumping, or conveying corrosive substances.

- Mining and Quarrying: In the mining and quarrying industry, stainless pulleys are used in conveyor systems to facilitate the transportation of mined materials. The durability and strength of stainless steel make it well-suited for handling heavy loads and abrasive materials.

- Wastewater Treatment: Stainless pulleys are employed in wastewater treatment plants where resistance to chemicals and corrosion is crucial. They are used in various equipment, such as belt filter presses or dewatering systems, to efficiently handle and process wastewater and sludge.

- Agriculture: Stainless pulleys are utilized in agricultural applications, including grain handling, seed processing, or livestock feed production. They provide reliable and efficient material handling solutions, ensuring smooth operations in agricultural facilities.

- Automotive and Manufacturing: Stainless pulleys find applications in the automotive and manufacturing industries, where they are used in assembly lines, robotic systems, or material handling equipment. Their durability and resistance to wear make them suitable for high-speed and repetitive operations.

- Packaging and Logistics: Stainless pulleys are employed in packaging and logistics industries to facilitate the movement of goods along conveyor systems. They ensure smooth and efficient transportation of packaged products, optimizing productivity and throughput.

- Architectural and Design: Stainless pulleys are also used in architectural and design applications for their aesthetic appeal. They can be incorporated into building facades, interior design elements, or decorative installations to provide both functionality and visual attractiveness.

These are just a few examples of the industries and applications where stainless pulleys are commonly used. The versatility, durability, and corrosion resistance of stainless steel make it a preferred choice in various sectors that require reliable and efficient material handling solutions.

editor by CX

2024-05-08